A new study demonstrates how remanufacturing within a circular economy delivers a wide range of benefits for society and the environment, as well as for business and the economy.

“A company that does not add value to society should not exist.”

Joe Kasser, Chief Executive of Siemens.

The circular economy is hot. Anybody worth their salt in the worlds of business and policy are talking about the need to go circular. We should not be surprised.

Arguably, the circular economy stands out more than any other innovation at this time — providing a genuine way forward for businesses and nations to deal with key sustainability challenges, while providing a viable means to continue economic growth within the limits of our finite planet. My friends, we appear to have a much need route through to a sustainable future!

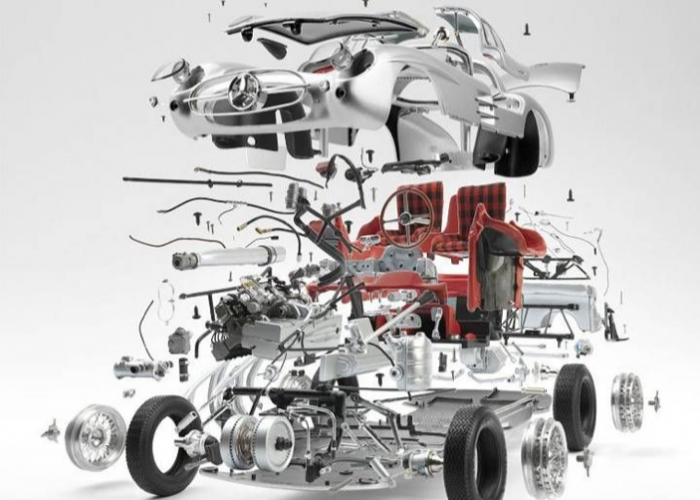

Remanufacturing is an important element within the circular economic transition. Simply put, if we can keep refurbishing and re-making products, we can keep valuable components and resources at their highest use for a much longer period of time. This means we can reduce the stress we place on the planet — as we extract fewer resources, use less energy and water, and produce less waste and emissions — than we would otherwise do, by continually making, selling and discarding lots of new products. This is clearly a much better deal than plain recycling.

While the idea of the remanufacturing within a circular economy looks attractive, there is a need to accelerate and scale up the transition. Making change within markets and business organisations is not always easy, we know. But, a common enabler for change is, of course, a compelling business case. Numbers talk.

There is a growing body of work promoting macro-level business and economic benefits, all helping to stimulate policy debate and strategic business interest towards a more sustainable model.

The Ellen MacArthur Foundation has established a material cost savings opportunity worth between US$ 380–630 billion, just within a subset of EU manufacturing. The EU points towards the potential for the circular economy to generate 580,000 new jobs, while reducing CO2 emissions by 450 million tonnes each year. There are clearly big financial incentives, as well as significant opportunities to reduce climate change impacts.

Given the growing urgency for more radical shifts in business sustainability performance, there is a growing need to demonstrate the triple-bottom-line benefits arising from circular economy models at a more granular level. Thankfully, there is a new study on the holistic range of benefits in support of individual businesses and start-ups adopting remanufacturing business models.

A New Breed: Positive Impacts.

Enter, Norsk Ombruk AS — a dynamic and ambitious remanufacturing company — established by Tommy and Jean Skjelbred in Norway in 2013. Norsk Ombruk´s big idea is all about taking old white goods — such as refrigerators, washing machines, stoves, dishwashers, and dryers — and restoring them into high-quality products that deliver a further five years of useful and productive life.

For the price conscious customer, there is a real tangible financial benefit: the remanufactured products can be purchased through reputable big-brand stores, with formal warranties, at half-the-price of new machines.

Last year, Norsk Ombruk remanufactured over 12,300 products, delivering an impressive range of benefits, worth a combined value of € 9.4 million. This represents a significant impact for a small, yet aspiring business.

By keeping thousands of remanufactured products active for a further five years, they have realised significant resource savings — avoiding the need to extract new materials.

Then, there are embedded energy savings, through avoiding the manufacture of new products — along with lifecycle energy savings from enhanced product energy rating performance. We can also extend this impact to include reduced carbon emissions — helping to reduce climate change impacts, and ensure readiness for future carbon pricing and natural capital policies.

One of the most significant benefits concerns the additional value delivered to customers and society — achieved by offering high-quality remanufactured products at half the price we might pay for new items. This is all about providing greater access and affordability, in particular for households that may be getting by on lower incomes.

The remanufacturing business model not only extends product life, it also extends brand life, too. The original brand — represented by a high quality remanufactured machine — keeps serving us, the customers, for longer. We are no longer enticed to throwaway and buy more. This reflects well on brand reputation in the new era of responsible business.

Original manufacturers (OEMs) also gain direct income for end-of-first-life products, with further benefits like reduced cost of inventory and logistics, enhanced reputation and brand loyalty, as well as future-proofing their business models.

A further societal benefit concerns reduced economic leakage. A formal remanufacturing business helps to keep products out the black market — currently, around 20% of discarded machines are stolen — which also generates skilled, longer-term tax-paying jobs.

Beyond Shared Value.

There are also some useful big picture metrics to express the value added through remanufacturing.

Norsk Ombruk delivers more value than it extracts. The ratio of benefits delivered, as a proportion of business operating costs, works out as 11:1. This means that for every € 1 million of operating costs, the company delivers € 11 million of benefits to people, the environment, business and the economy.

It is worth noting that 56% of the financial benefits delivered by Norsk Ombruk flow directly to society. This goes way beyond the talk of shared value — this is all about shared wealth!

The remanufacturing company also recognises its impacts help support of the greater movement towards achieving the UN Sustainable Development Goals — from poverty reduction, to climate action, to inclusive growth: remanufacturing makes a valid contribution.

Given the range of positive impacts, it is perhaps not surprising that Norsk Ombruk is growing at a significant rate — within planetary limits. Following a successful start-up phase, the company is now expanding its operations into other countries in Europe and Scandinavia — including Recirk.dk, a new business division recently opened in Denmark.

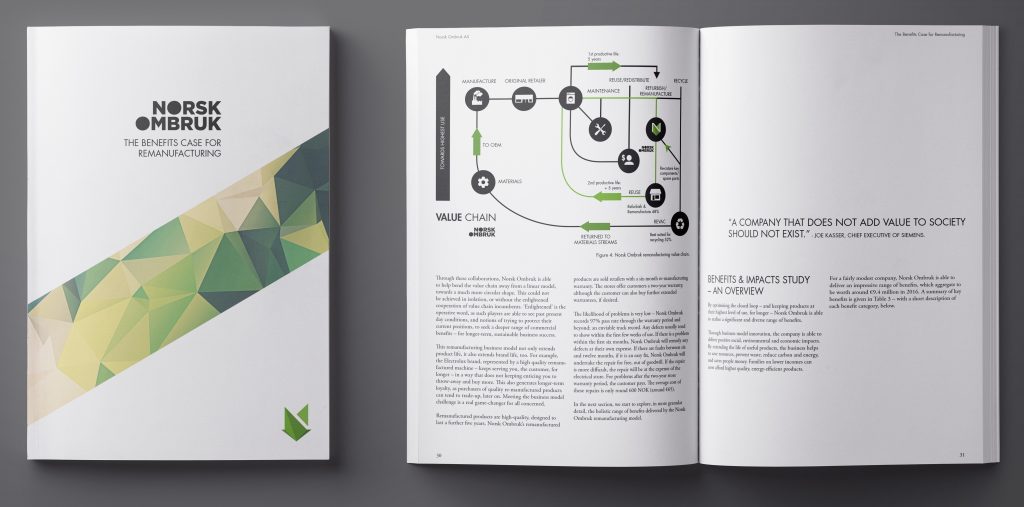

But, this level of success could not be achieved in isolation, or without the enlightened cooperation of other key players in the value chain. Norsk Ombruk´s approach is supported by a range of collaborations, working in partnership with incumbent OEMs like Electrolux — Norsk Ombruk is able to source an increasing volume of old products, through which it can produce its range of remanufactured products.

Furthermore, working in partnership with retailers like Elkjøp and IKEA, Norsk Ombruk has access to mainstream sales channels — maximising the opportunity for customers to see and purchase high-quality remanufactured products, as a viable alternative to new products.

Through these essential collaborations, Norsk Ombruk is able to help bend the value chain — away from a take-make-waste linear approach, towards a much more circular model.

Future Perfect?

There is much more to come; the opportunity in this space is huge — with lots of potential feedstock for remanufacturing, out there. Collectively, we are sitting on a global mountain of underutilised, valuable resources — trapped within old and discarded products. Waste is money. The value of e-waste alone, worldwide, represents around $52 billion worth of potentially reusable resources.

Today, only 35% of discarded e-products end up in official collection and recycling systems. Many of these assets are ripe for remanufacturing and re-use — if we could only invest and develop the infrastructure and capabilities required to realise this potential.

Norsk Ombruk shows us what is possible; how remanufacturing can become a practical reality, delivering a broad range of significant benefits for people, planet, and businesses — as well as the economy, as a whole.

Going forward, further collaboration will be needed with OEMs to enable greater design for remanufacturing — to aid more productive working, and expansion of this important market. We will also need a more supportive policy environment, to encourage sustainable consumption and remanufacturing. For example, future policy incentives might include a reduction in the level of VAT on professionally remanufactured goods.

No doubt, there will be big challenges, and lots of hard work ahead — yet, as the Norsk Ombruk study demonstrates, the benefits are certainly worth the effort. And, pretty soon, any business worth its salt will have to demonstrate the real value added to society — beyond the bottom line — by delivering shared wealth.

—

Mike Townsend is founder and chief executive of Earthshine Group, and author of The Quiet Revolution (Routledge, forthcoming).

This article was originally published on Huffington Post.

For more information you can download a free copy of Norsk Ombruk: The Benefits Case for Remanufacturing.

Follow Mike Townsend on Twitter.